Colliflower, LLC

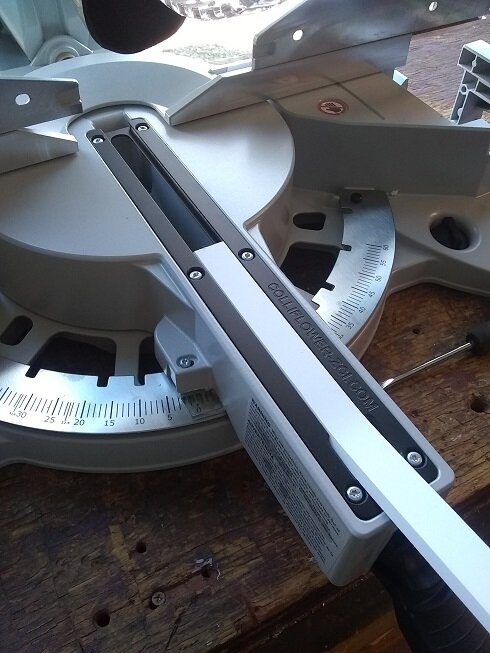

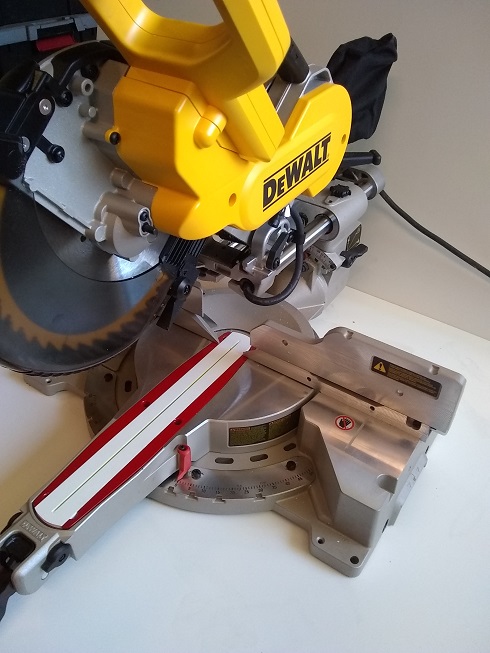

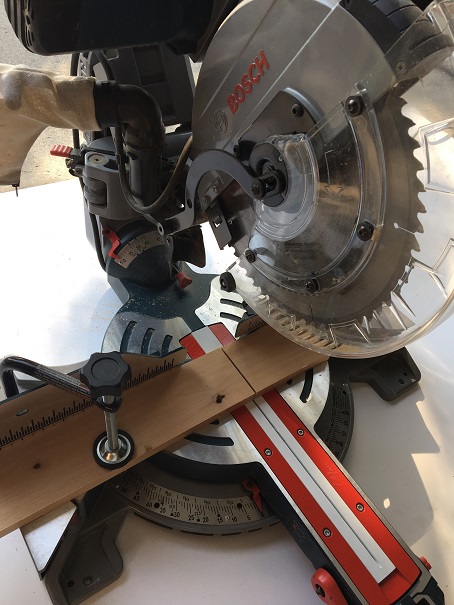

Colliflower, LLC started as a company set on improving the quality of table saw and miter saw throat plates by making lasting (metal) replaceable-insert zero-clearance plates. Out with the cheap plastic plates and in with the anodized (and now powder coated) aluminum, perpetual ZC plates.

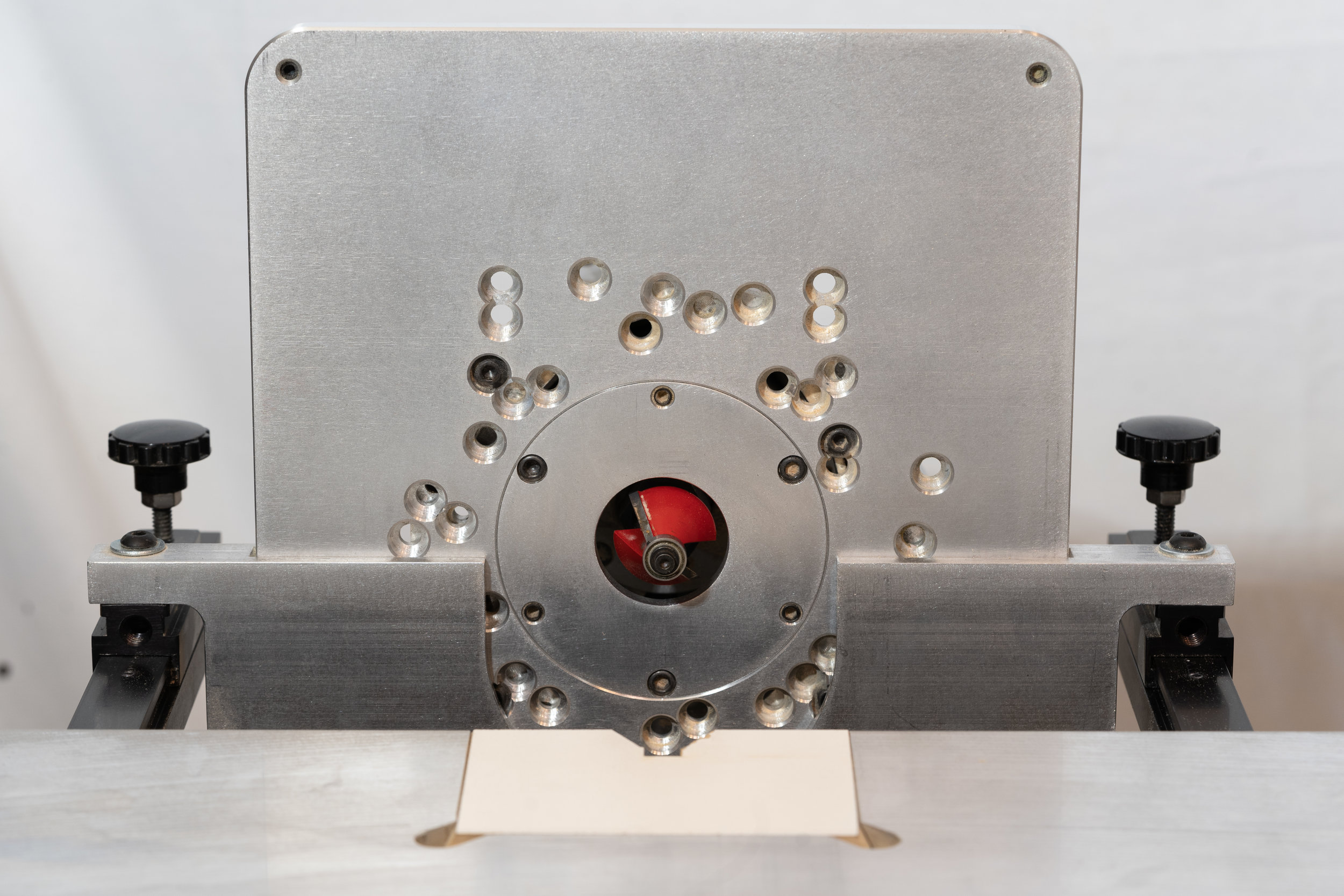

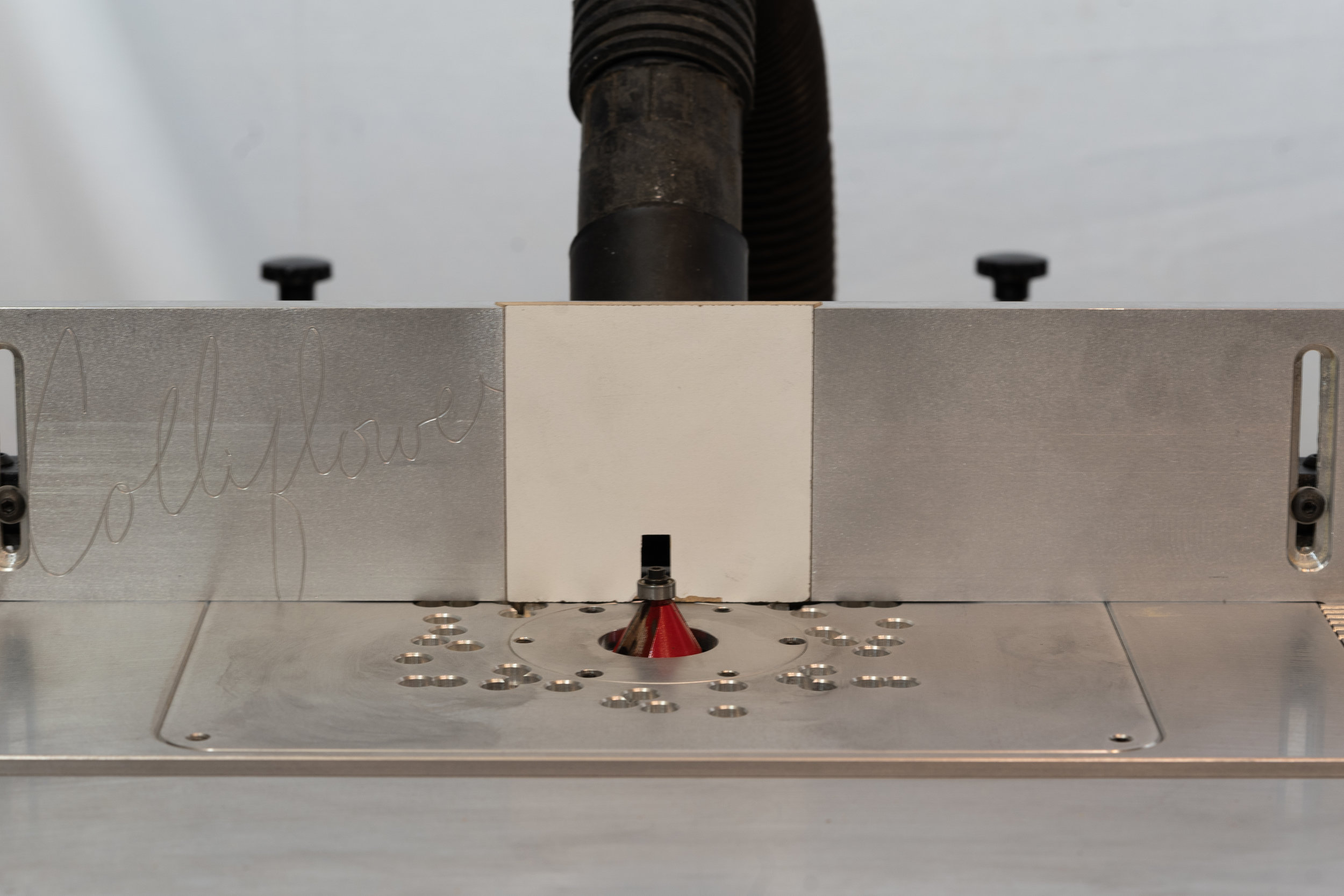

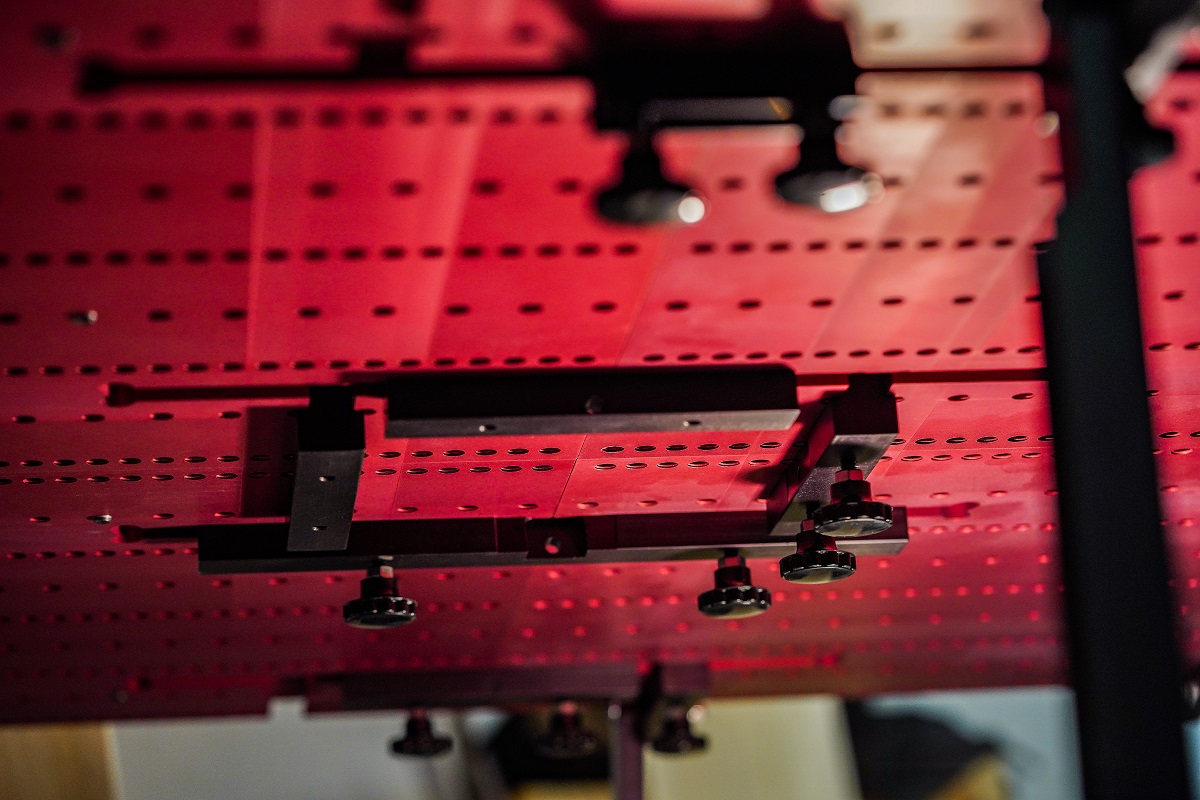

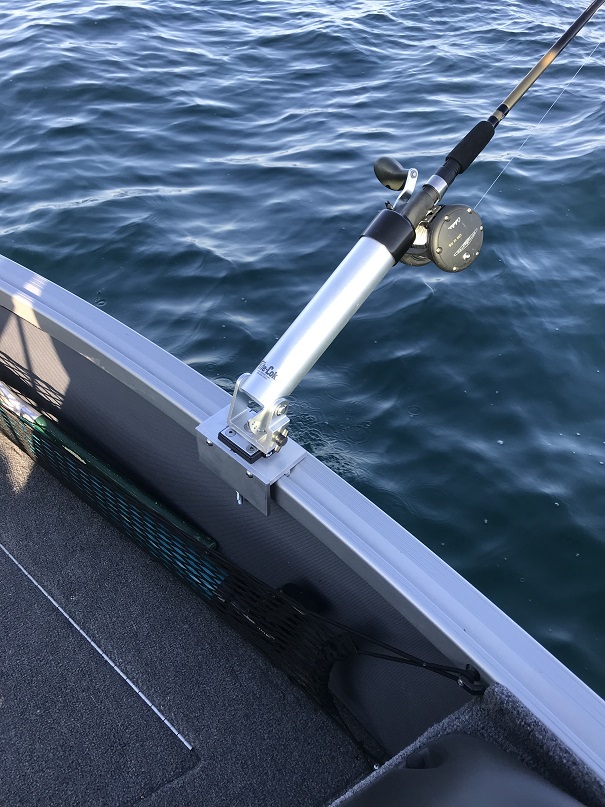

Colliflower, LLC then moved on to improving work-holding and clamping in the metalworking world, the riding experience in the Ducati cruiser world, the routing and workstation experience in the wood working world, and the fishing (downrigging) experience in the Alumacraft world. (We are the original makers of a downrigger mount that is compatible with the Alumatrac.)

In summary

Simply put, our goal in business and life is to "Make it Better"—for you, for us, for everyone.

Sincerely,

Colliflower

"Make it Better"

P2 Router Table

Ride in Comfort

Cleaner Cuts

Perfect-Fit Downrigger Mount